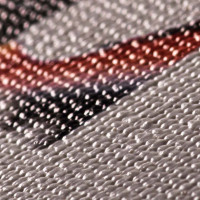

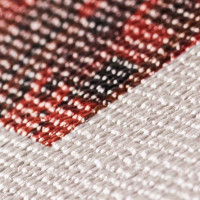

Base Composition refers to what the substrate (base) is made of. Most of our bases are made from cotton, polyester, alpha-cellulose, or blends of all three. Cotton is prized for it’s structural stability and excellent color retention, while polyester ensures crack free stretching of canvas. To maximize the benefits of both materials, most of our canvas is made of a 65/35 cotton/polyester blend.

Base Composition refers to what the substrate (base) is made of. Most of our bases are made from cotton, polyester, alpha-cellulose, or blends of all three. Cotton is prized for it’s structural stability and excellent color retention, while polyester ensures crack free stretching of canvas. To maximize the benefits of both materials, most of our canvas is made of a 65/35 cotton/polyester blend.  This refers to how smooth the surface of a canvas or paper appears.

This refers to how smooth the surface of a canvas or paper appears.  Gloss. Satin. Matte. These are largely generic terms to batch categorize the sheen or how light-reflective a product is. Typically, a product with a GU (see Gloss Level) of 0-4 is considered Matte, 5-8 Satin, and 9+ Gloss. You may notice we add additional distinctions to further clarify where a product falls within these ranges e.g. High Gloss or True Matte.

Gloss. Satin. Matte. These are largely generic terms to batch categorize the sheen or how light-reflective a product is. Typically, a product with a GU (see Gloss Level) of 0-4 is considered Matte, 5-8 Satin, and 9+ Gloss. You may notice we add additional distinctions to further clarify where a product falls within these ranges e.g. High Gloss or True Matte. OBAs aka Optical Brightening Agents aka Optical Brighteners are fluorescent molecules added to the inkjet coating of fine art media to enhance the whiteness and brightness of the product. Effective though these additives may be, OBA’s have a short usable life after which they “burn out,” leaving the media permanently yellowed and faded. Think of OBA’s as filler- an inexpensive way to add bulk or improve the appearance of something while adding little or no substantive value. If you are looking for a paper or canvas that won’t deteriorate with age, be sure to check the product page for our Archival Certification and check the product specs to confirm that it’s OBA-free.

OBAs aka Optical Brightening Agents aka Optical Brighteners are fluorescent molecules added to the inkjet coating of fine art media to enhance the whiteness and brightness of the product. Effective though these additives may be, OBA’s have a short usable life after which they “burn out,” leaving the media permanently yellowed and faded. Think of OBA’s as filler- an inexpensive way to add bulk or improve the appearance of something while adding little or no substantive value. If you are looking for a paper or canvas that won’t deteriorate with age, be sure to check the product page for our Archival Certification and check the product specs to confirm that it’s OBA-free.

Also expressed as g/m2 or Grams per Square Meter, this measurement represents the total weight of a one-meter by one-meter square of a given substrate. The higher the number, the heavier the material. There is not a direct corollary between GSM and Caliper, rather GSM is a function of Base Composition, Texture, Caliper, and the amount of coating applied.

Also expressed as g/m2 or Grams per Square Meter, this measurement represents the total weight of a one-meter by one-meter square of a given substrate. The higher the number, the heavier the material. There is not a direct corollary between GSM and Caliper, rather GSM is a function of Base Composition, Texture, Caliper, and the amount of coating applied.

Measured in mils (1/1000th of an inch), like the tool with which it shares a name, Caliper is used to demarcate the thickness of a media.

Measured in mils (1/1000th of an inch), like the tool with which it shares a name, Caliper is used to demarcate the thickness of a media.

The measurement of how impenetrable to light or see-through a product is. Opacity is measured from 0% (fully transparent) to 100% (fully opaque). Products with 100% opacity completely block all visible light.

The measurement of how impenetrable to light or see-through a product is. Opacity is measured from 0% (fully transparent) to 100% (fully opaque). Products with 100% opacity completely block all visible light.

.png?timestamp=1597822828) This is how we determine the white point of a media. L*, a*, and b* (correctly pronounced L-star, a-star, and b-star) refer to distinct measurements that help us determine the absolute color of our media. The L* value measures luminance/lightness on a scale from 0 (black) to 100 (white). The 'a' and 'b' values measure Chrominance (color) with 0 being neutral; a* measures the red/green value and b* measures the blue/yellow value.

This is how we determine the white point of a media. L*, a*, and b* (correctly pronounced L-star, a-star, and b-star) refer to distinct measurements that help us determine the absolute color of our media. The L* value measures luminance/lightness on a scale from 0 (black) to 100 (white). The 'a' and 'b' values measure Chrominance (color) with 0 being neutral; a* measures the red/green value and b* measures the blue/yellow value. The standardized and measurable expression of “Finish,” Gloss Level rates the sheen or how light-reflective a product is. Typically, a product with a GU of 0-4 is considered Matte, 5-8 Satin, and 9+ Gloss.

The standardized and measurable expression of “Finish,” Gloss Level rates the sheen or how light-reflective a product is. Typically, a product with a GU of 0-4 is considered Matte, 5-8 Satin, and 9+ Gloss.

Indicates the inside diameter of the roll's core. Most large-format printers have a spindle designed with adapters able to accommodate both 2" and 3" core sizes. Breathing Color uses yield maximizing Padded Core technology for aqueous canvas rolls allowing printing to the very end of the roll. Competitors non-padded cores can generate as much as 10% gross waste per roll.

Indicates the inside diameter of the roll's core. Most large-format printers have a spindle designed with adapters able to accommodate both 2" and 3" core sizes. Breathing Color uses yield maximizing Padded Core technology for aqueous canvas rolls allowing printing to the very end of the roll. Competitors non-padded cores can generate as much as 10% gross waste per roll.